I. Main ApplicationsThe Tibial Tray Fatigue Testing Machine is primarily used to evaluate the f

WhatsApp: +86 13816217984

E-postadress:info@qinsun-lab.com

YY/T 0810 (China): Specifies fatigue testing protocols for tibial trays in total knee arthroplasty, focusing on support and protection of plastic bearing surfaces.

ASTM F1800 (International): Defines methodologies for evaluating the fatigue strength of tibial components under cantilever loading conditions.

ISO 14879-1: Additional compliance for general fatigue testing of total knee joint prostheses.

Cantilever Loading Precision: Advanced actuator design ensures uniform stress distribution per ASTM F1800 requirements.

5 Million Cycle Endurance: Proven capability to complete YY/T 0810’s 5×10⁶-cycle fatigue test without calibration drift.

Dynamic Load Control: Closed-loop system maintains R=0.1 stress ratio during sinusoidal/random loading (0.1–10 Hz).

Real-Time Fracture Detection: AI-powered acoustic emission monitoring identifies micro-cracks at sub-millisecond intervals.

Intuitive Workflow: 21.5” capacitive touchscreen with gesture control and pre-loaded SOPs for 10+ implant geometries.

Modular Environmental Chambers: Quick-swap pods for simulated physiological (-20°C to +50°C) and corrosive environment testing.

Electromagnetic Actuator: 3.000 N peak force capacity with programmable load ratios (R=0.1–10).

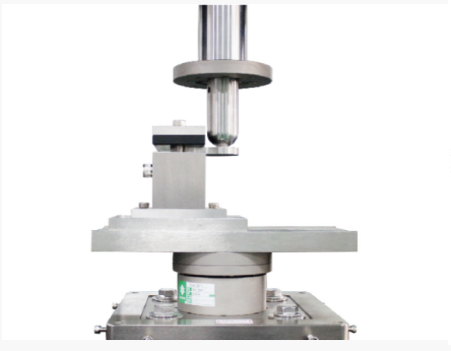

Cantilever Loading System: Simulates physiological knee joint moments with ±20 mm axial displacement.

Dynamic Load Control: 0.1–10 Hz frequency range with programmable waveforms (sine, square, random, custom).

Thermal-Mechanical Chamber: ±0.3°C temperature stability with integrated humidity control (10–95% RH).

High-Speed Imaging Ready: Syncs with external cameras for full-field strain mapping (DIC optional upgrade).

Safety First: Triple-redundant emergency stop, overload clutches, and laser-based specimen breakage detection.

Tibial Tray Test Fixture Kit:

Self-centering collet system (28–40 mm tibial tray compatibility)

Laser-aligned loading anvils with diamond-like carbon (DLC) coating

Thermal-Mechanical Chamber:

15L capacity with rapid cooling/heating (15°C/min)

316L stainless steel interior with HEPA filtration

TestMaster Ultimate Software:

Automated S-N curve generation and fatigue limit calculation

21 CFR Part 11-compliant audit trail with blockchain timestamping

Remote monitoring via dedicated iOS/Android app

Operator Kit:

Calibrated torque wrench set (0.5–50 Nm)

Specimen alignment gauges (ASTM F1800 compliant)

Calibration Bundle:

NIST-traceable force calibration weights

Temperature/humidity verification probe

Safety Kit:

Laser safety curtains

Acoustic enclosure with 30 dB noise reduction

| Parameter | Specifikation |

|---|---|

| Max. Dynamic Force | ±3.000 N (6.000 N peak optional) |

| Frequency Range | 0.1–10 Hz (0.01 Hz increments) |

| Load Ratio (R) | 0.1–10 (adjustable) |

| Axial Displacement | ±20 mm (0.1 μm resolution) |

| Torque Capacity | ±20 Nm (0.01 Nm resolution) |

| Temperaturområde | -20°C to +50°C (environmental chamber) |

| Luftfuktighetskontroll | 10–95% RH (non-condensing) |

| Data Sampling Rate | 100 kHz (synchronized across 16 channels) |

| Power Requirements | 220V/110V ±10%, 50/60Hz, 2.000W |

| Dimensions (W×D×H) | 1.500 × 1.000 × 2.000 mm |

| Vikt | 750 kg (including environmental chamber) |

| Noise Level | <65 dB (A-weighted) |

Ansvarsfriskrivning: Ovanstående innehåll är endast för referens och kommunikation mellan branschinsider, och garanterar inte dess riktighet eller fullständighet. Enligt gällande lagar och förordningar och förordningar på denna webbplats ska enheter eller individer som köper relaterade artiklar erhålla giltiga kvalifikationer och kvalifikationsvillkor.

Företagstelefon

+86-21-6420 0566

Arbetstider

måndag till fredag

Mobiltelefon:

13816217984

E-post:

info@qinsun-lab.com