I. Product Overview The Fleece Loop Length Tester is a specialized instrument designed to measure t

WhatsApp: +86 13816217984

E-postadress:info@qinsun-lab.com

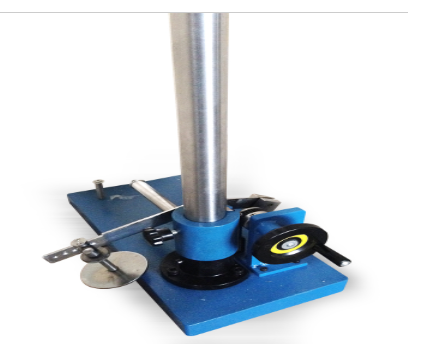

I. Product Overview

The Fleece Loop Length Tester is a specialized instrument designed to measure the fiber loop length distribution in fleece fabrics, critical for evaluating softness, bulkiness, and durability. It utilizes non-contact laser scanning technology to ensure precise and repeatable measurements aligned with international textile standards.

| Parameter | Specifikationer |

|---|---|

| Measurement Principle | Laser micrometer + AI pattern recognition |

| Resolution | ±0.5 μm (ISO 137 standard validation) |

| Provstorlek | 100×100mm (adjustable clamping frame) |

| Scanning Speed | 300 mm/s (full-area mapping) |

| Power Supply | 220V/50Hz, 0.8kW |

| Mått | 500×400×700mm (W×D×H) |

Ansvarsfriskrivning: Ovanstående innehåll är endast för referens och kommunikation mellan branschinsider, och garanterar inte dess riktighet eller fullständighet. Enligt gällande lagar och förordningar och förordningar på denna webbplats ska enheter eller individer som köper relaterade artiklar erhålla giltiga kvalifikationer och kvalifikationsvillkor.

Företagstelefon

+86-21-6420 0566

Arbetstider

måndag till fredag

Mobiltelefon:

13816217984

E-post:

info@qinsun-lab.com